Frode Laursen Eskilstuna

Creating an overall sustainable construction

A logistics centre of 39,000 m² is currently being established in central Sweden. Sustainability is a key requirement for the developers from the start; transport company Frode Laursen. The aim is to reduce the environmental impact of the plant both during the construction phase and during operations. The energy-efficient and recyclable solutions of ROCKWOOL as well as the new, climate-friendly production of stone wool insulation was an ideal choice.

Saving energy, water and other resources

The large, modern facility is a central Nordic hub that serves the food trade throughout the Nordic region. During the construction phase, sustainability is considered in the selection of materials, and 100% renewable energy must be used in operations. The facility includes both warehouse and logistics areas, an administrative building and a wash lane for trucks, in which all the domestic water is recycled.

“Our ambitions are strongly aimed at reducing environmental impact both during construction and operations. Our approach is best described with the motto ‘the greenest energy is the energy not used’. Therefore, during the entire project, we considered which solutions could save energy, water and other resources in the future use of the building,” states Jakob Gundal Nikolajsen, building manager at Frode Laursen.

Jakob Gundal Nikolajsen continues, “We have been working closely with ROCKWOOL for many years. The transition to fossil-free energy sources in the Nordic factories ensures a more sustainable production of stone wool, which is well suited for our purpose, because we constantly pursue sustainability principles in our construction.”

Increasing fire protection

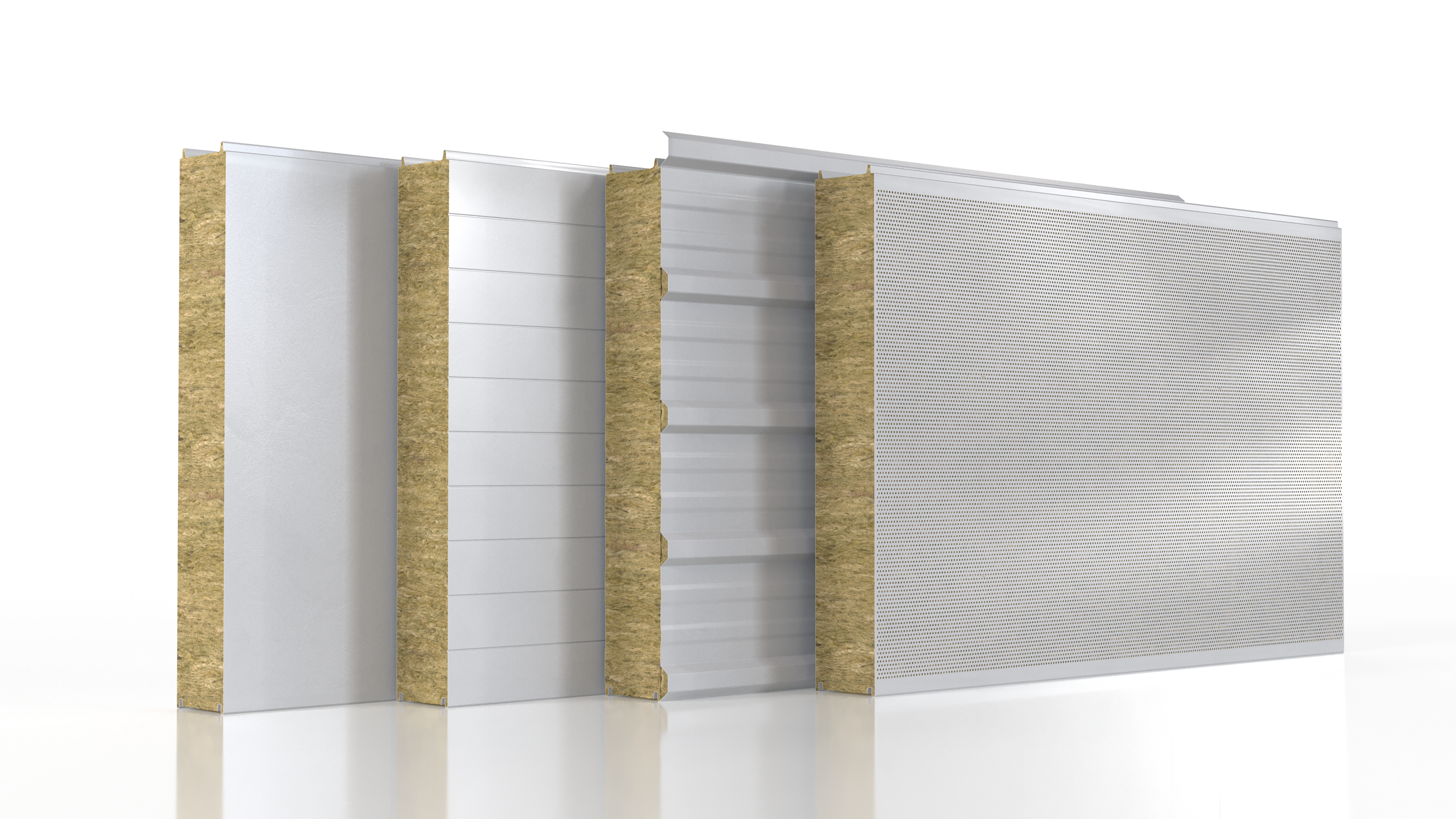

For the project, ROCKWOOL supplied stone wool insulation for the roofs, walls and facades, which increase fire protection and ensure a stable construction.

A total of 16,000 m² of sandwich panels were installed for the exterior walls (200mm stone wool insulated sandwich panel) and partition walls (100mm stone wool insulated sandwich panel) containing ROCKWOOL stone wool insulation core material (fire classification rating Euroclass A2-s1, d0 according to EN 13501-1). In addition, stone wool’s recycling capacity fits perfectly into the sustainable construction agenda.

Project location

Frode Laursen

Eskilstuna

Sweden

One system, many advantages

The administration building itself is built in ROCKWOOL’s complete wall system Rockzero. It is an efficient system of load-bearing walls, which ensures fast assembly, maximum utilisation of square metres and a construction without thermal bridges.

“The Rockzero system is a diffusion-open construction that is breathable and therefore offers both a significantly better room climate as well as a better acoustics. The improved indoor climate will benefit the people working in the building.

In addition, Rockzero is a fireproof solution, and the entire construction is inorganic, which means that moisture and mould do not occur,” explains Jakob Sjøl, project sales manager at ROCKWOOL Nordics.

In addition to the advantages of mounting and the thinner walls, which ensure more net square meters, the Rockzero system also has a high insulation value, which enables savings in energy consumption and thus a reduction in operating costs.

Focus on a greener future

Frode Laursen was recently awarded Transport Company of the Year in Denmark for its green transformation. The solutions used in the construction of the large, modern logistics centre also show how the company works with sustainability at all levels. The new logistics centre will be operated with 100% renewable energy, intelligent energy monitoring and controlled LED lighting for low energy consumption, rainwater and heat recovery.

“With such a large project, it is exciting to take innovative products and use them to create an overall sustainable construction that solves some of the challenges, we know we will encounter in the future in terms of environment and nature. The close dialogue with both the client and the contractor building with the Rockzero system has made it possible for us to find a perfect solution which also meets the high environmental requirements. It has been a good and exciting collaboration across the board,” says Jakob Sjøl about the project.

The new logistics centre will be completed in 2022 in Eskilstuna, Sweden.

Project Data

| Construction period | 2021 - 2022 |

| Area / square metres (m²) | 39,000 |

| Client | Frode Laursen |

| Contractor | Logistics service provider |

| Products | Rockzero, Hardrock |

| Sandwich panel supplier | Tenax Panel - ROCKWOOL Core Solutions insulation in sandwich panels (Spanrock™) |

| Rockpanel facade solution services: | RockCycle® – ROCKWOOL recycling scheme for recycling stone wool |