Volvo car showroom

A dealership building that promotes customer experience

Read it on coresolutions.rockwool.comA car showroom that aligns with Volvo’s branding and customer experience to reflect Scandinavian values of calm, clean lines and create the feeling of ‘cool on the outside and warm on the inside’.

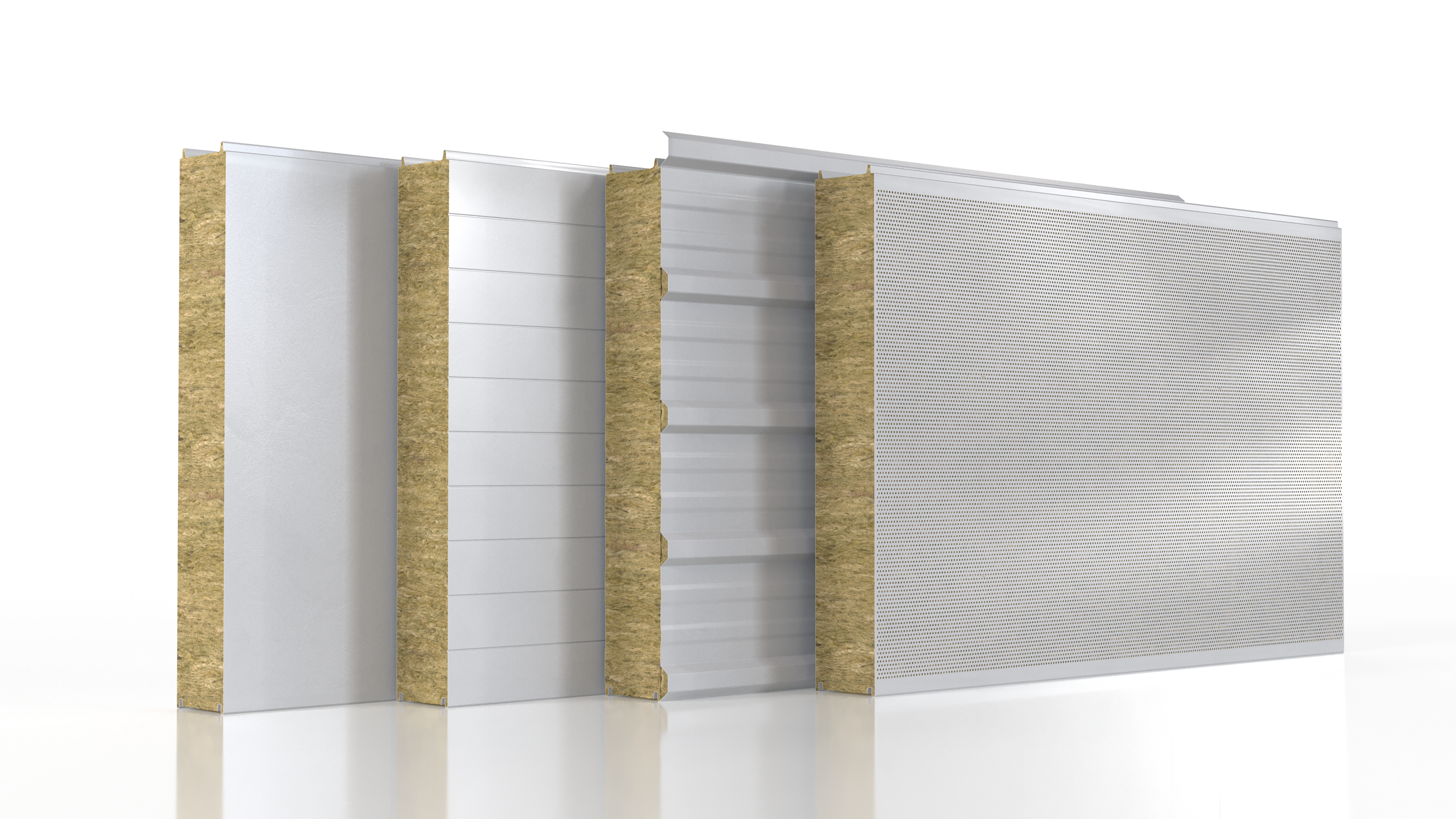

The building creates visual impact by featuring the latest Volvo car in a rooftop jewel box and a façade that combines illuminated glass for visual impact. Stone wool insulated sandwich panels provide a muted backdrop that adds fire resistance, thermal and acoustic performance.

You can find this case study in the reference book “Building with stone wool insulated sandwich panels”, authored by Professor Imperadori. Learn more and access the book here.

Architecture that aligns with branding

As a leading automotive company, Volvo’s dealerships provide a consistent experience for customers while showcasing its latest vehicles. The buildings are designed to have a relaxing atmosphere according to guidelines in the Volvo Retail Experience (VRE). This concept was developed by the Wingårdhs architectural practice in Gothenburg.

The EURO KAS Volvo dealership in Katowice, Poland, is a good example of the VRE’s deployment. It was built in 2017-18 in partnership with Volvo’s own in-house architect.

The building makes an impact with a main façade made from frosted glass, a natural wooden framed doorway and a ‘jewel box’ on the roof for EURO KAS Volvo to showcase its latest vehicles. This façade floods the interior with natural light during the day. Then, when night falls, it can be illuminated with lighting in

colours to emulate the Northern Lights.

Other facades are based on sandwich panels in RAL 9006, a soft grey tone that provides a muted and functional backdrop to keep Volvo’s cars in focus.

Volvo car showroom

Katowice | Poland

Aligned with Scandinavian design principles

As a Swedish company, Scandinavian design is central to Volvo’s brand. The dealership features functional spaces, natural light and uncluttered lines. Its colour scheme is based on muted tones with carefully placed accents, while materials and furnishings are selected to be long-lasting and sustainable. These principles extend to the sandwich panels that form the building envelope. The panels are 1150 mm wide and are installed in a vertical orientation using the same grid as the frosted glass panels. This creates a clean and unobtrusive finish.

The panels are manufactured in Poland from steel sheets with an insulating core. In some areas of the building, panels use insulation made from stone wool and provides fire protection, as well as thermal and acoustic performance. Other areas feature PUR foam.

The panels are extremely durable, particularly with a stone wool core. Stone wool has been found to maintain its mechanical and thermal properties for more than 65 years. This is an important consideration in the automotive world, where dealership relationships with brands last for decades. A further benefit is the adaptability of sandwich panels, which means that EURO KAS can make changes to its building over time.

Finally, at the end of a building’s life, both the stone wool and steel elements of a sandwich panel can be remelted and recycled into new materials with no loss of performance, making these sandwich panels a sustainable choice.

Dry construction for efficient project delivery

Another important benefit of sandwich panels is the speed and efficiency of construction. It’s possible to use digital design and manufacturing tools such as BIM to design a scheme that includes visuals as well as a material specification.

This digital approach enables a contractor to order the right number of sandwich panels in the required sizes with all the accessories needed to complete the installation. This protects cashflow by avoiding waste and it also saves time on site as the panels arrive in kit form ready to install.

Cradle to new cradle

Circularity of materials was a key factor in the Platys centre achieving sustainability certifications. The scheme was designed to minimize consumption of resources and raw materials.

Magnoli & Partners specified recycled and recyclable materials that meet the principle of “cradle to new cradle”, which has the goal of protecting the Earth’s resources. This principle ran through project procurement and design, as shown by the modularity of components produced off-site, such as steel structural elements and sandwich panels.

Speed and efficiency

While design engineering takes longer with sandwich panels, they save 30 to 50% of the overall project time as the offsite manufacture of the panels can take place at the same time as site approvals and earthworks.

Speaking to local media Katowice Wyborcza, Janusz Świeboda, Vice-President of the management board for EURO KAS Volvo said: “Everything was carried out in consultation with Volvo Car Corporation. Architects from Gothenburg came to us and an architect from Volvo Car Poland supervised the investment and design process.”

Project Data

| Client: | Volvo EURO KAS Poland |

| Architect: | Volvo Cars Poland |

| Sandwich panel supplier: | ARPANEL |

| Cost of construction: | Around PLN 14 million (equivalent to EUR 3.3 million) |

| Construction period/timescale: | October 2017 – July 2018 |

| Products: | 4,000 m² of ARPANEL S MiWo sandwichpanels with Micro 14 corrugated profile and a RAL 9006 “White aluminum” finish. ARPANEL CH PUR cold store sandwich panels |