The goal of Egger was to design a state-of-the-art manufacturing facility that would be flexible to accommodate future market demand, while incorporating the latest and most innovative technologies in production automation.

EGGER Group, an Austrian-based, privately-held, familyowned manufacturing company, is a global leader in the manufacturing of wood-based materials for the furniture and interior design, flooring and building products industries. In 2017, the company sought to expand its operations in the North American market with a $700 million manufacturing facility and corporate office, located in Linwood, North Carolina. Egger Wood Products broke ground in March 2018, with the goal of becoming operational within 18 months. Gray Construction, Inc. was missioned to design and build the manufacturing facility, which began operations with the production of raw particleboard and thermally fused laminate (TFL) panels in September of 2020. Construction and expansion of the plant have been ongoing, and when complete will employ approximately 875 people.

The Goal

The goal was to design a state-of-the-art manufacturing facility that would be flexible to accommodate future market demand, while incorporating the latest and most innovative technologies in production automation. It would need to reflect the company’s commitment to sustainability and mission “to create more from wood,” while also achieving practical and functional design and performance objectives. Additionally, the facility’s construction would need to address specific risk management issues, including moisture control and fire protection.

The Challenge

High heat and humidity are generated within the plant as a result of the manufacturing processes, particularly within the press building where particleboard is producedusing extreme pressure and very high temperatures. Moisture and condensation control would be an absolute necessity and would also need to address contrasting weather conditions in other areas of the plant such as unconditioned warehouses. Risk mitigation in the form of fire protection was also top of mind, given the volume of wood product present as finished solutions for the market, in addition to the cross-laminated (CLT) structural joist construction of the production facility. Accustomed to European building standards, EGGER Wood Products sought to match high-performance goals while adapting to U.S. construction standards. Long-term durability and resilience were also important objectives.

The Solution

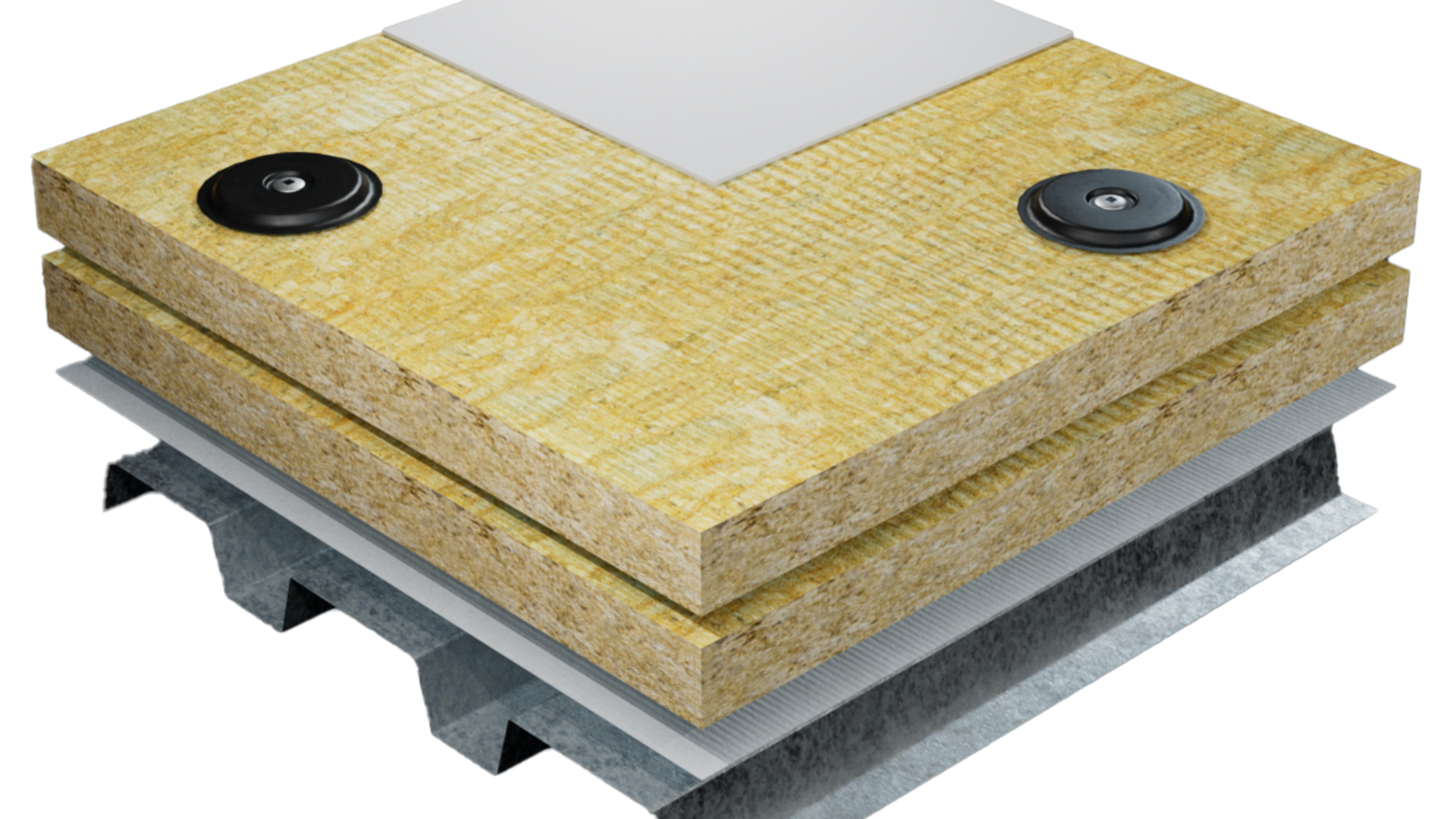

EGGER Mechanically Fastened Roof Assembly:

- Membrane: 60mm Sikaplan RhinoBond PVC

- Mechanical Fasteners: #15 6” fasteners with Sarnadisc RhinoBond Polymer Coated Plate

- 2 layers of 3” ROCKWOOL Toprock® DD

- Vapor Retarder SA 31

- Metal Deck

EGGER’s insulation of choice was ROCKWOOL stone wool insulation. The roof was the primary application with stone wool also installed behind the exterior façade panels. ROCKWOOL conducted both energy and hygrothermal modelling to determine the best solutions for the roof assemblies. In all, over 3.2 million board feet of ROCKWOOL Toprock® DD and 16,000 sq. ft. of Multifix™ were specified.

The products’ dimensional stability, density and strength were very important to this particular roof application, given the roof system’s 6” deck dimension. The rigidity of ROCKWOOL Toprock® DD met the requirements to span the flutes of the metal deck and provide proven long-term dimensional stability. Toprock® DD was installed in two layers to meet the targeted thermal requirements, with the joints carefully staggered to help reduce thermal bridging.

Opting for ROCKWOOL roof insulation was also strategic in that it eliminated the need for coverboard, reducing cost and layers in the roof system and saving time on the job site—an important factor given the tight construction schedule. A small portion of the roof assembly called for an adhered membrane. In this application, Multifix™ provided the added benefit of a mineral-coated fiberglass facer, simplifying install directly over the insulation. Over the mechanically-fastened Toprock® DD, the membrane was induction welded. Contractors touted the ROCKWOOL stone wool insulation’s ease of install and ability to be easily cut for a custom fit around penetrations, allowing for tight joints. The dimensional stability and density of stone wool helped it remain firmly in place, withstanding heavy traffic during installation.

Thermal and moisture control was vital at the Linwood facility, not only because of the varied conditions within certain areas of the facility—from hot and humid in some areas to unconditioned in others—but also due to the local climate. Outdoor temperatures range from a low of 31°F in January to a high exceeding 106°F with outdoor humidity ranging from 70 – 76 year-round. Nearly half the year (161 days) sees some kind of precipitation. Given the high potential for moisture exposure, the vapor permeability of the ROCKWOOL stone wool roofing products was a significant benefit, allowing any moisture to dry out, mitigating the risk of mold and reducing potential for condensation or moisture damage.

The inherent non-combustibility of stone wool contributed to EGGER’s goal of achieving a safer working environment. Its high melting point and ability to resist temperatures of up to 2,150°F was an appealing benefit surrounding risk mitigation on the job site during construction, given that stone wool is ignition resistant with a 0 flame spread and 0 smoke development index. The ROCKWOOL stone wool roof insulation boards also contribute to reducing risk during the operations of the facility—by safeguarding people and property in the event of a fire.

ROCKWOOL stone wool solutions dovetailed exceptionally well with EGGER’s strong commitment to sustainability and the environment. EGGER’s raw particleboard and TFL panels produced at the Linwood plant are made primarily using what would otherwise be considered waste or recovered wood—wood chips left over from other milling and manufacturing processes. This pre-consumer recycled material comprises about 70% of the wood in the composite panels produced at the facility. Likewise, ROCKWOOL stone wool insulation is made from natural, abundant and renewable raw materials in highly sustainable processes. Both companies believe in a circular process. With the addition of a new on-site recycling center, EGGER’s raw particleboards and TFL can be produced with up to 20% post-consumer recycled material, which is primarily used or broken wood pallets and packing materials, as well as wood material from construction and demolition projects. Similarly, ROCKWOOL stone wool products can be recycled back into the manufacturing process to create new stone wool products, reducing waste at its factories.

ROCKWOOL and EGGER have each set strong, attainable and measurable sustainability targets to achieve double-digit carbon reduction goals by 2030. With this type of sustainability profile, EGGER’s desire to use a greener building insulation that considers the environment, reduces the impact on society, and provides a vast array of performance advantages, made sense. This, combined with top notch technical, building science and sales/specification support, gave ROCKWOOL stone wool the competitive edge, ultimately helping EGGER achieve its multitude of complex goals at its impressive North American facility.

EGGER Wood Products

Linwood, NC