Precast Concrete Wall Panel System

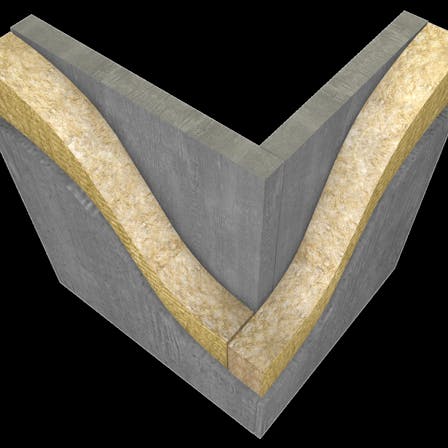

ROCKWOOL’s customer’s precast concrete sandwich panels have a 2.5” concrete front plate (outside of building) followed by 6” of ROCKWOOLTM CONROCK 60 insulation in the middle of the wall , plus the back plate/inside wall is 5.5” structural concrete. The main part of the wall design is that the outside concrete panel does not touch the inside concrete panel to minimize thermal bridging in the walls.

ROCKWOOL Products Installed

ROCKWOOL’s CONROCK 60 is rigid stone wool (mineral wool) insulation board designed specifically for sandwich panel systems (SWP). CONROCK 60 used in a wall system can aid in providing superior protection and comfort by providing dimensional stability, consistent thermal performance, and acoustical benefits along with excellent fire resistant and moisture management properties.

Impact of CONROCK 60 in the Precast Concrete Wall Panel System

Thermal bridging has a similar 15% impact on the wall as a typical wood framed wall.1 In Southern Arizona (Climate Zone 2), the wall system is expected to perform similar to an R52 light wall.1 The combined impact of Thermal Mass resulted in an effective R-value of the wall being R44. A comparable wood framed wall assembly would need to be 2x6 construction with R20 batt and 4” of polyiso, 5” of XPS, 6” of ROCKWOOL IS, or 7” of EPS2 exterior sheathing.1 Total nominal R value is 26.0. Inclusive of the 15% impact of thermal bridging a nominal R value of 22.1 is achieved.1 The Concrete Sandwich Panels in this system have minimal thermal bridging and a large thermal mass that acts more like an R40+ building.

Project Location

Southern Arizona

Project Timeline:

2013 – 2014